Treat Quality Control as Belief

Langfang bonai has been focusing on Roof sheet production for 15 years. We do it for you.

Strictly inspect and record all links from raw materials, key production links, finished products, and container loading.

products, and container loading.

Every detail of your roof sheet is strictly by world-class standards.

01

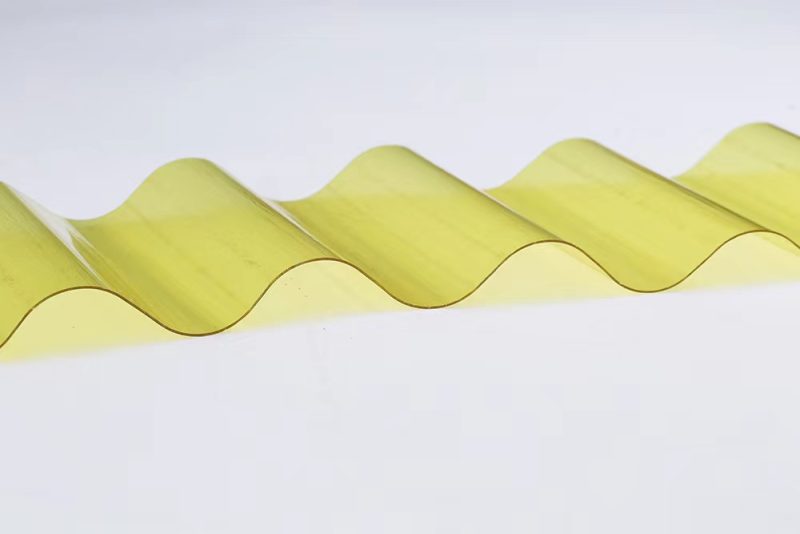

corrugated plastic panels

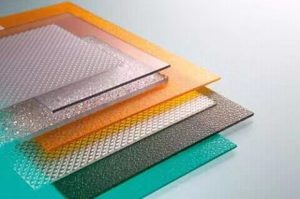

[caption id="attachment_1345" align="alignnone" width="300"] polycarbonate roofing systems

polycarbonate roofing systems

polycarbonate roofing material

polycarbonate roof for terrace[/caption]

[caption id="attachment_1346" align="alignnone" width="300"] polycarbonate insulated roof panels

polycarbonate insulated roof panels

foamed polycarbonate vs polycarbonate[/caption]

02

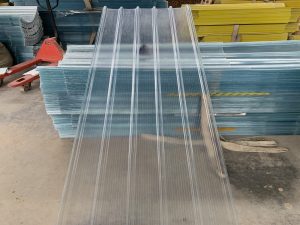

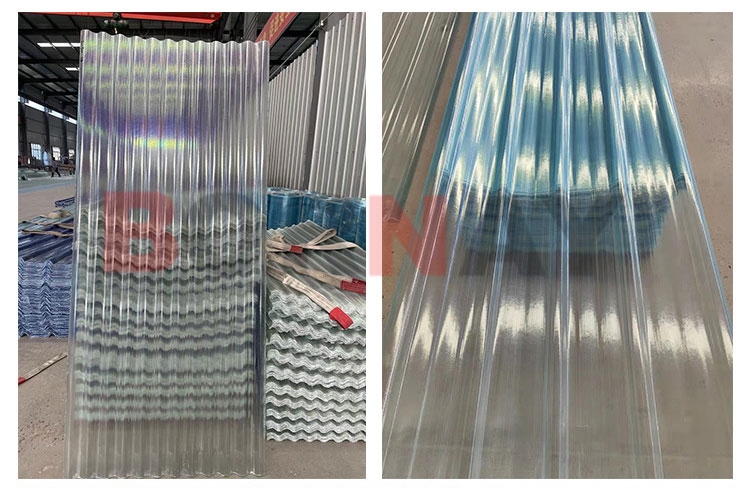

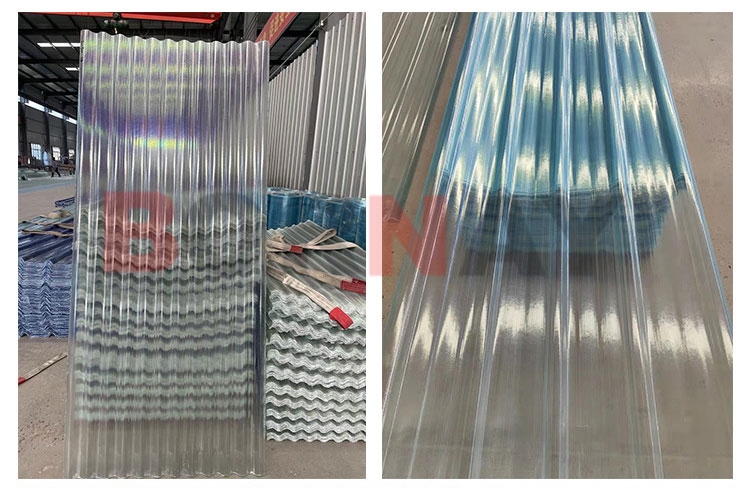

frp sheet

[caption id="attachment_1348" align="alignnone" width="169"] polycarbonate flat roof panels

polycarbonate flat roof panels

what is polycarbonate roofing

residential polycarbonate roof[/caption]

[caption id="attachment_1308" align="alignnone" width="300"] Fiberglass roof transparent skylight corrugated tiles[/caption]

Fiberglass roof transparent skylight corrugated tiles[/caption]

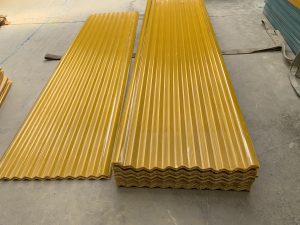

[caption id="attachment_1324" align="alignnone" width="300"] calamina de aluminio

calamina de aluminio

techo de calamina

modelos de techos de calamina

calaminas para techo

techo calamina

precio de calamina de 3.60[/caption]

[caption id="attachment_1332" align="alignnone" width="300"] calamina de acero galvanizado[/caption]

calamina de acero galvanizado[/caption]

03

Tablero hueco de policarbonato | placa alveolar de policarbonato|Placa de policarbonato de panal

Langfang bonai Honeycomb polycarbonate sheets are part of our Twin-wall, double-wall polycarbonate hollow sheet category.

The basic structure of a Langfang bonai Honeycomb polycarbonate twin-wall hollow sheet involves two layers of thin flat sheets which are connected by vertical ribs of the same material, though in the case of Honeycomb sheets, the thin flat sheets are interconnected with a mass hexagonal prismatic polycarbonate cells, mimicking that of a bee’s honeycomb.

Known in geometry as the honeycomb conjecture, equal sized cells are created between the partition while minimizing the total perimeter of the cells. In other words, a hexagonal structure utilizes the least amount of material to create a lattice of cells within a given volume.

Honeycomb structures offer great same thermal insulation properties in that each cell acts as a separate chamber and individual layer to trap air within; the combined effect of the cells minimizes the transmission of heat, which makes the covered area more energy efficient.

Honeycomb hollow polycarbonate sheets can be seen as a light weight alternative to Solid Flat Polycarbonate Sheets. Its hollow structure makes the weight many times lighter compared to solid flat sheets at the same thickness, but retains the strength and structural integrity of polycarbonate sheets.

• Great thermal insulation properties

• Lighter weight than solid panels

• Excellent rigidity and impact resistance

• Available with a variety of color and light transmission options

• Superior structural durability

• Weather and UV resistant

• Blocks virtually all UV radiation

• Easy to handle and install

04

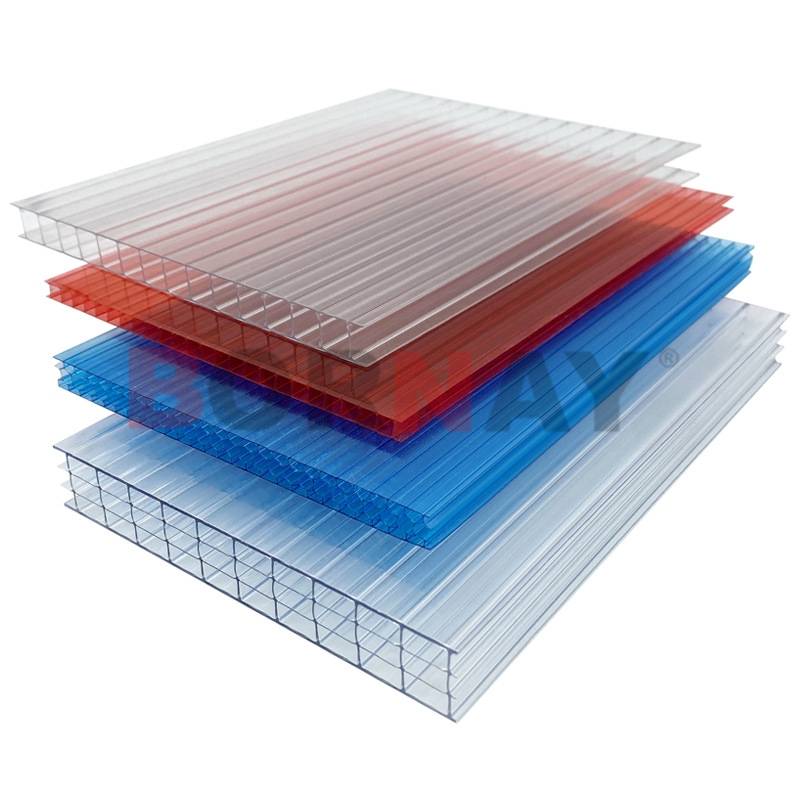

pc hollow sheet|polycarbonate sunshine sheet|pc hollow panel

Polycarbonate hollow sheet is made of polycarbonate (referred to as PC) material at high temperature. It has excellent properties such as heat preservation, flame retardant, UV protection, wind and rain resistance, light weight, sturdy and durable, and good aging resistance. The PC hollow sheet produced by our company is a high-quality sheet with a 10-year warranty. It is mainly used for the construction of large-scale projects such as canopy, carport, small flower house construction, highway noise barrier, and greenhouse .

Langfang bonai 's products can provide a variety of sheet colors, such as transparent, milky white, grass green, lake blue, mountain blue, brown, dark brown, etc., as well as custom-made sheet siz

Type of PC hollow board

Product Feature

Thickness :4/6/8/10/12/14/16/18/20mm

Kinds: Twin-walls/triple-walls/four-walls/Honeycomb /X-structure

Width :1220/1560/1820/2100mm

Guarantee:10 years

Length :5800/6000/11800/12000mm or Customized

Color :Brick red, maroon, gray, blue, green,customized color

Accessories

LANGFANG BONAI EP TECH CO.,Ltd. was established in 2008, covers an area of 15,000 square meters, has an investment of 12 million,and has 76 employees, including 3 R&D personnel. In 2010, it introduced two FRP continuous production lines and 3 antique tile production lines from Australia. 2 PC production lines, with an annual output value of more than 80 million

05

Cost Advantages and Economic Benefits Analysis of FRP Roof Panels

Introduction: Fiber Reinforced Polymer (FRP) roof panels have gained popularity in the construction industry due to their numerous advantages, including cost-effectiveness and economic benefits. This article aims to analyze the cost advantages and economic benefits of FRP roof panels, highlighting their positive impact on project budgets and long-term savings.

Conclusion: In conclusion, the cost advantages and economic benefits of FRP roof panels make them an attractive choice for construction projects. Their lower initial costs, durability, energy efficiency, low maintenance requirements, and sustainability contribute to long-term savings and positive environmental impact. By considering FRP roof panels, project stakeholders can optimize their budgets and create sustainable buildings that stand the test of time.

06

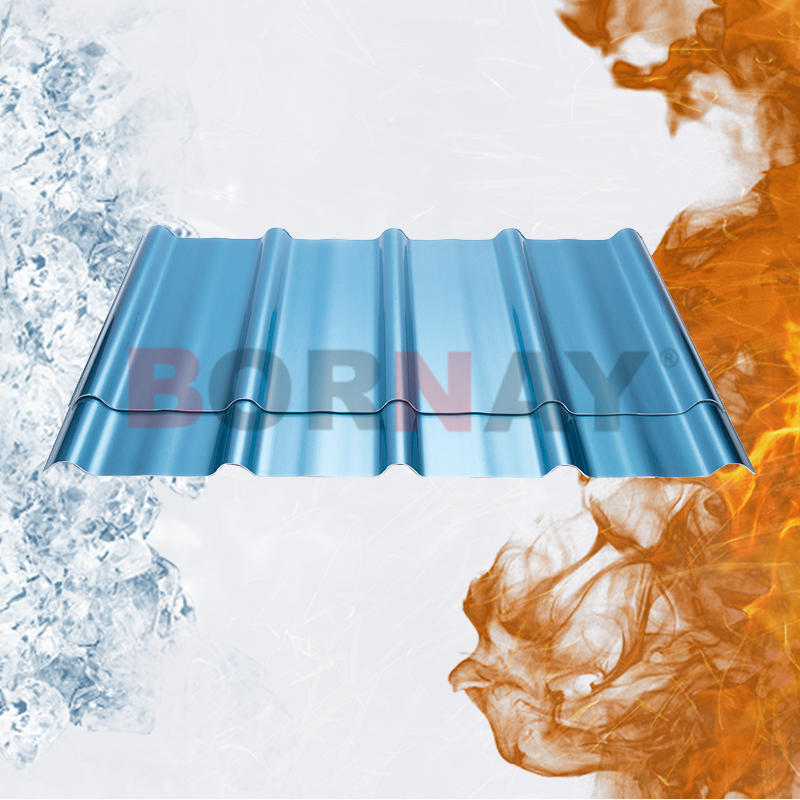

Waterproofing, Thermal Insulation, and Fire Resistance Characteristics of FRP Roof Panels

Introduction: Fiber Reinforced Polymer (FRP) roof panels have gained significant popularity in recent years due to their numerous advantages, including lightweight construction, high strength-to-weight ratio, and resistance to corrosion. This article aims to explore the key features of FRP roof panels, with a focus on their waterproofing, thermal insulation, and fire resistance characteristics. By understanding these properties, architects, engineers, and construction professionals can make informed decisions when selecting FRP panels for roofing applications.

I. Waterproofing Characteristics of FRP Roof Panels (Approximately 1000 words)

1.1 Moisture Resistance: FRP roof panels possess excellent moisture resistance due to their inherent non-porous nature. The panels are typically manufactured using a combination of polymer resins, such as polyester, vinyl ester, or epoxy, which provide an impermeable barrier against water intrusion. This property ensures long-term protection against leaks, water damage, and the growth of mold or mildew.

1.2 Seam Integrity: One critical aspect of waterproofing is the integrity of panel seams. FRP panels can be fabricated in large, seamless sections or joined using adhesive bonding or mechanical fastening techniques. Properly sealed seams prevent water penetration and ensure the overall waterproofing effectiveness of the roof system.

1.3 UV Resistance: FRP roof panels are often engineered to withstand prolonged exposure to ultraviolet (UV) radiation. UV-resistant coatings or additives can be incorporated during the manufacturing process to enhance the panel's durability and prevent degradation caused by sun exposure. This feature is particularly important in regions with high sunlight intensity.

1.4 Maintenance and Longevity: FRP panels require minimal maintenance to preserve their waterproofing properties. Routine inspections and cleaning are generally sufficient to ensure continued performance. With proper installation and maintenance, FRP roof panels can have a long lifespan, offering reliable waterproofing for decades.

II. Thermal Insulation Characteristics of FRP Roof Panels (Approximately 1000 words)

2.1 Low Thermal Conductivity: FRP roof panels exhibit low thermal conductivity, meaning they are efficient in reducing heat transfer through the roof structure. This property helps to maintain a comfortable indoor environment and reduce energy consumption for cooling or heating. By minimizing heat loss or gain, FRP panels contribute to overall energy efficiency in buildings.

2.2 Insulation Options: To further enhance the thermal insulation capabilities of FRP roof panels, additional insulation materials can be incorporated. Common options include polyurethane foam, polystyrene, or mineral wool, which are placed between the FRP panel and the roof structure. These insulation layers provide increased resistance to heat flow and improve the overall thermal performance of the roof system.

2.3 Condensation Control: Effective thermal insulation also helps to control condensation within the roof assembly. By reducing the temperature differential between the interior and exterior surfaces, FRP roof panels minimize the risk of condensation formation. This feature prevents moisture buildup, which could lead to structural damage or mold growth.

III. Fire Resistance Characteristics of FRP Roof Panels (Approximately 1000 words)

3.1 Flame Retardancy: FRP roof panels can be engineered to possess excellent flame retardant properties. Through the use of fire-resistant additives and manufacturing techniques, the panels achieve high fire resistance ratings. This characteristic is vital for ensuring the safety of occupants and minimizing the spread of fire within buildings.

3.2 Low Smoke Emission: During a fire event, FRP roof panels with low smoke emission properties release minimal amounts of toxic smoke. This feature is crucial for maintaining visibility and facilitating safe evacuation during emergencies. By reducing smoke production, FRP panels contribute to improved fire safety measures within a building.

3.3 Structural Integrity: In addition to fire resistance,

07

RAW MATERIAL QC

All raw materials used in the manufacture of roof panels are 100% virgin to ensure material stability; we have established long-term business relationships with the best suppliers of floor mat polycarbonate, resin, fiberglass and UV coatings, and carry out Regular inspections ensure that every shingle is maintained to the highest industry standards.

08

Critical Step QC

The production process is a key step in inspection. The thickness of the core material is set and carefully checked by a fully automatic professional automatic machine. UV coating and irradiation ensure stable surface properties and scratch resistance. The click system will be tested by professional tension instruments.